Schütz are launching new Green Layer Technology

Schütz will soon be offering their Green Layer Technology in the United Kingdom. With these IBCs and Drums, Schütz aim to increase the proportion of recycled materials even further.

For a number of years now, Schütz have been recycling old bottle, plastic pallets and drums by grinding them down and turning them into new plastic pallets to be used on their IBCs. Of course the pallets never come into contact with the users product directly for obvious reasons but that left Schütz with a difficult task, especially when faced with the up and coming “Plastic Tax” set to hit the industry soon.

Schütz Green Layer IBCs consist of three layers; the outer and inner layers – the ones that come into contact with the user and the product are both brand new polymer, much like every other brand new IBCs that Schütz produces in any of its plants across the globe. The middle layer however is made of recycled polymer, as this never comes into contact with anything other than the two layers it is sandwiched between.

These Green Layer IBCs are available with UN 31 HA1/Y Certification and whilst at the moment they are only available in a black bottle configuration they do come with sight strips and Schütz are also looking at a natural bottle option too.

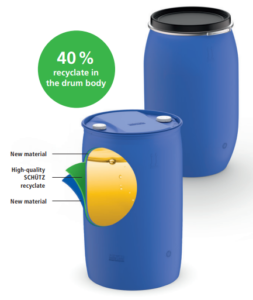

Schütz are also offering Green Layer Technology on their range of drums too. These drums work in the same way as the IBCs, with the inner and outer layers being new virgin polymer and the middle layer between them being made up of the recycled material. Schütz are also offering these drums with or without Hazardous Goods Approval, which conforms to UN Certifications.

But how are Schütz able to gather the large amount of polymer to recycle? Schütz have had a recycling ticket service now for decades which always keeps their stock levels at a happy average. These IBCs are generally; condition dependent, stripped of their old bottles, and rebottled before being sent back out again. Schütz will now be taking these bottles and putting them through their own regranulating and recycling centres, which use several mechanical preliminary stages to shred and clean the inner bottle before they are then put back into the loop as either middle layer granuals to be use on the new Green Layer Technology range, or into the plastic pallets should they not meet the optimum standard that Schütz will require for these to be within the bottle iteself.

Of course Schütz will be policing this and making sure that everything is in order and is not only safe but secure for its customers, something that Schütz has held highly since it’s founding.

Pensteel are looking to source some of these IBCs for our customers too, however as these are new to the market and the demand at the moment needs to grow there will likely be minimum order quantities on these IBCs and drums. If you would like more information on these products, please email us at sales@pensteel.co.uk and we will gladly assist and share information on this exciting new range products.