IBC Handling Information

If you are uncertain of the compatibility of your products with the container bottle or seals please contact Pensteel for advice

Handling Instructions:

Before Filling:

• Check that the pallet, cage and bottle and valve are suitable for use with the intended product

• Ensure that the valve is securely tighten to the inner bottle and that the valve is closed

• Check that the inside of the bottle is clean

• When hot filling product do not exceed 65°C

• When bottom filling make sure that the vents are functioning correctly

• Do not over fill the IBC

• After filling ensure that the lid seal is correctly positioned, and tighten the screw cap to 70-80 Newton/Meters

Handling and transportation

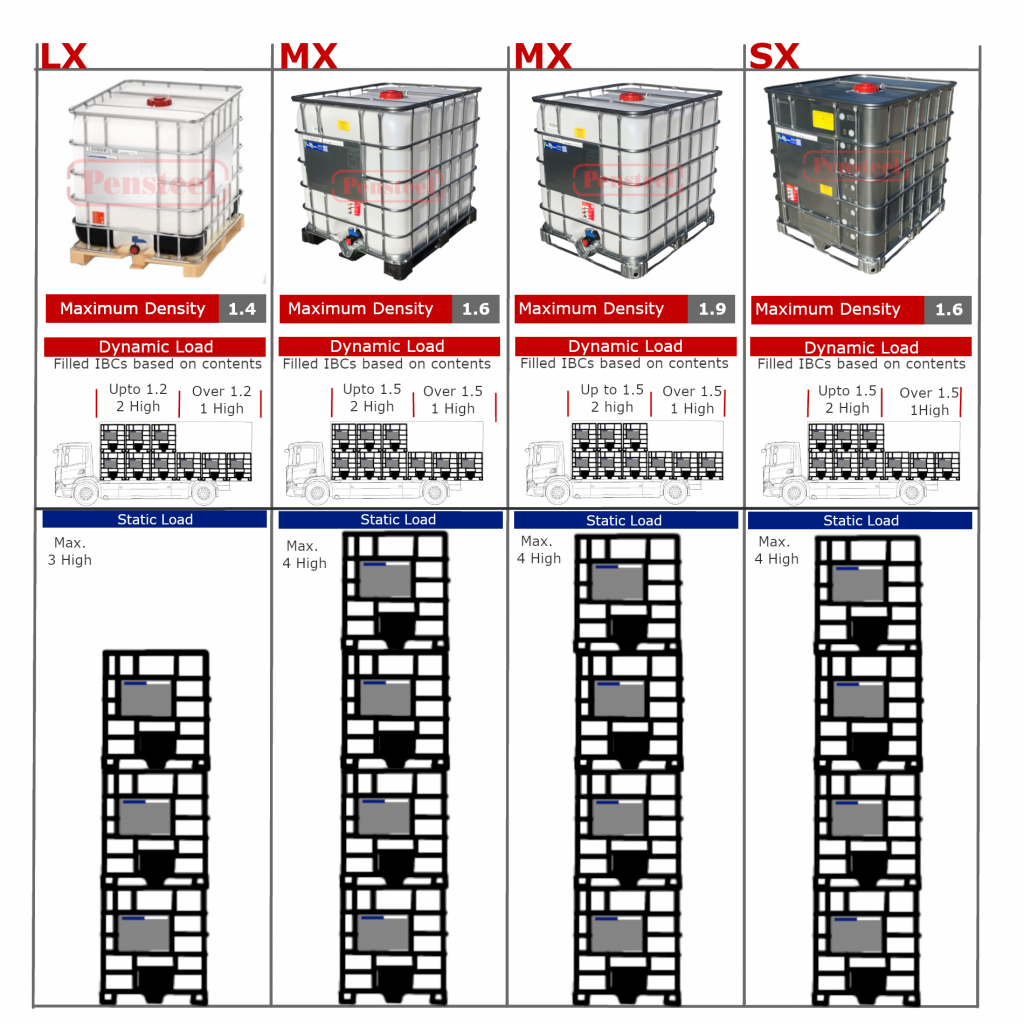

• Do not stack filled IBCs without checking the details below, if in doubt please contact Pensteel for advice

• Do not lift IBCs from the top frame

• Ensure that the fork truck tines are fully inserted under the IBC before lifting

• Ensure that the vehicle floor is in good condition and free of all nails etc that could puncture the IBC

• If you wish to transport more than a single layer of filled IBCs then please check below

• Always transport IBCs with the correct labelling attached to the ID plate

• Always secure IBCs to prevent possible movement during transit

Before Empting

• Please ensure that a vacuum is not created by loosening the inlet screw cap

• All couplings connected to the outlet valve must be supported

• Do not tighten couplings onto the outlet valve using wrenches, spanners, stilsons Etc

• Do not pressurise the container to aid discharge

• After emptying always close and secure the outlet valve

Storage

• If storing the IBC in warehouse racking always use a slave pallet, do not store IBCs unsupported