IBC Tank Terminology & Meanings

The world of IBCs can seem daunting at first, especially when you’re not quite sure what you’re looking for. This can be made even worse when companies start using terms such as “BSP” “FSSC” or “Camloc”. At Pensteel, we not only aim to serve large organisations, but also people who are after single IBCs for allotments that may not be too up to speed with all of the different terminilogy and meanings.

In light of this, we’ve decided to put together a small list of the most common phrases that confuse people and explained them in the simplest terms

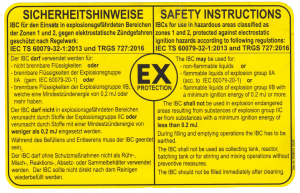

EX – Certain liquids need to be stored or transported in certain IBC Tanks. Any liquid with a flashpoint of less than 60 degrees Celsius MUST be stored in an EX-Rated IBC. Our SX-EX and MX-EX Foodgrade IBC Tanks are two examples of this. “EX” Rated equipment refers to equipment that has been classified for safe use in hazardous areas. Non-EX IBC Tanks can emit small sparks or static discharge when filling or emptying, which can have catastrophic consequences when low-flashpoint liquids are involved.

FSSC – FSSC or Food Safety System Certification, means that an IBC Tank is certified for use in the Food Industry. It can be used to store potable water, syrups, soft drinks and most other foodstuffs. Some liquids in the food industry may require both FSSC and EX ratings, such as whiskey, or other low flashpoint alcohols. For these liquids, we can offer an MX-EX-FSSC container. Please note that Food Certification is only valid for the first time the container is used.

S60 x 6 – The S60 x 6 thread is the thread found on most Schutz IBC Tanks with a 50mm valve. The thread itself is very coarse, making it easy to recognise. Pensteel are able to offer various adaptors to take S60 x 6 thread to BSP and Camloc type fittings.

BSP – A BSP, or British Standard Pipe Thread can come in many sizes, from ¼ inch all the way up to 3 inches off the shelf. We are also able to offer larger size BSP adaptors, if this is something you require then please contact us. BSP threads are very fine, and therefore cannot be attached straight to a Schutz IBC. Pensteel are able to offer adaptors to allow BSP threads to mate with Schutz IBC Tanks.

S100 x 8 – The S100 x 8 thread is the thread found on Schutz’s 3 inch/80mm valves. As with its 2 inch counter-part, the thread is very coarse, making It easily distinguishable from a BSP or similar thread.

Pensteel are able to offer adaptors that allow other 3 inch parts to connect to a Schutz IBC Tank with this thread, as well as reducers which allows the use of 2 inch parts on this 80mm valve.

Camloc – Camloc valves and adaptors are somewhat rarer than their S60 x 6 or BSP counterparts. Instead of using threads to connect to adaptors, camloc valves use a dry-coupler system. Camloc valves do also have a thread for screw caps – this thread is incredibly fine and the caps are almost flat, again making them easy to distinguish. A camloc adaptor that fits to an IBC will also generally have large metal arms, which allows the adaptor to couple with the IBC Tank. Pensteel are able to offer a range of camloc adaptors from 2 inch to 3 inch.

Anti-Pressure/Anti-Vacuum/Pre-Vac – An Anti-Pressure vent is designed to stop large pressure build-ups within an IBC Tank. Often during storage or transport, certain liquids can emit vapours or pressure which if left unchecked can cause an IBC Tank to split, crack or even in some cases explode if no anti-pressure vent is fitted.

Anti-Vacuum vents are designed to stop an IBC Tank from collapsing in on itself during discharge. It may not sound like anything too serious if an IBC Tank collapses in on itself when a user is emptying it, however this can end up being quite violent and can easily bend and warp the metal cage and pallet and can also even split the plastic bottle too. An anti-vacuum vent solves this issue by allowing air into the IBC, replacing the product that is being emptied from it.

A Pre-vac, or anti-pressure, anti-vacuum vent is capable of doing both of the previous tasks, allowing pressure out, and also allowing air in when discharging.

Certain liquids, such as fuels, have flammable vapours and fumes, which can escape from an anti-pressure vent. Pensteel are able to offer flame gauzes for these. In the event of the fumes igniting, they will not be able to pass through the flame gauze, meaning the product in the IBC won’t end up going off in one go.

RJT – RJT Fittings or Ring Joint Type Fittings are usually used in the food industry as they’re able to be dismantled and cleaned easily. RJT Threads look a little more coarse than a BSP thread, however they are generally thinner or shorter, however if you’re unsure of which thread you have or require, then please contact us.